Here is a quick tutorial on how to install 3rd party heated seats to your Dart, if it didn’t come that way form the factory. I live in Chicago, and I called around to get estimates on heated seats installed – they ranged from $250.00 – $400.00 per seat. This was a bit more than I was ready to spend, as I thought I could do it easily myself – wrong! Actually, it’s not that difficult, but it certainly isn’t as simple as many of the other mods. If you are patient, and take your time, you can do it, as well.

This is the seat kit I bought from Amazon, but it is also available on ebay, as well:

Here is the link on Amazon that I purchased, and here is the equivalent ebay link. I spent $25.00 on the kit, which included two carbon fiber heating elements, a three way switch, (high, low, off) wire, inline fuse, and relay. You will also need an add-a-fuse if you pull power from the inner fuse block. I recommend giving it a fuse location that supports at least 20 amps, but 15 will work.

Here is everything that came in the kit, including (wait for it)… instructions! Voila!

Here is a closeup of the relay and the switch:

First thing, and most important, is grab yourself a 6 pack. It is very important you enjoy your time with your Dart. Vodka also works well.

Next step, is to disconnect the battery – failure to do so, will result in a trip to the dealer to reset your seat airbags, and if you love the dealerships like my friends know I do, you won’t be a happy camper.

Then, you have to disconnect the harness going to the seat, which is located underneath, and can easily be accessed from the floor in front of the seat. You simply pull a small plastic lever down, which releases the connection. Then you will need a T40 wrench with a bit of a handle on it, as the bolts may be a bit tight. There are three exposed T40 bolts, and one covered by a plastic trim piece in the rear, inside location (third pic below, on the right) which is removed by a single phillips screw.

Anyone that comments about my dirty carpet can kiss my A$$. lol.

Now the seat can be removed. Recline the seat all the way back, and pull it out through the rear door. Get out your vacuum, as you will never have these exposed like this for cleanup. Once the seat is out, grab another beer, then pry outward on the lower plastic pieces at the rear of the seat where the back pivots.

Underneath that piece you will find a single phillips screw – remove that, as well as the phillips along the side, on that same plastic piece left. I only removed the outside plastic, as the inside one was able to be lifted up enough to access the large 5/8″ bolts holding the top and bottom of the seat together.

This is the part that can be bent outward to expose the bolts:

This is what it looks like underneath that plastic cap:

The two bolts have been removed in this picture: (5/8″)

This is the inside piece, that comes completely off. This is what those magic bolts look like:

Before you pull the halves apart, there is a single plastic connector holding them together for the airbags.

Now you can get to the seat seams – They are held together by their own force with a plastic rail. Push the fabric in together to release tension, then they come apart pretty easily.

Once you get the first plastic rail set apart, there is yet another plastic rail set inside, that also is removed the same way:

If you want to change the seat covvers, or completely remove them, they are helkd together by two reverse zippers along each side. I did NOT remove this – there is plenty of room to stick your hands inside the fabric to access where the heaters go.

The bottom front seat cover is held in the same way – a plastic rail set. Mine also had a small metal screw securing it, but it didn’t look factory, so I’m not sure. Pull the fabric forward to relieve the stress and slide them apart. Again, it doesn’t take much force to do so.

The seat adjustment handle comes off by prying up the plastic cover and removing three phillips screws inside:

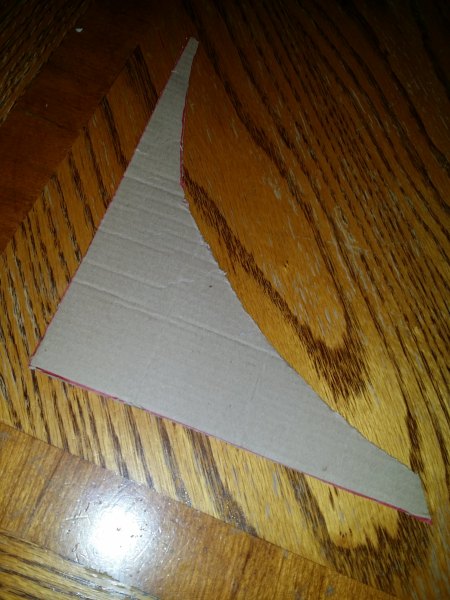

Mine had hog rings down all of the seams, so those have to be pried apart. I didn’t have hog ring pliers, so I used some heavy needle nose. Once you free the first 3 or 4 rings, you can then slide the heat element under the fabric, and secure it with the adhesive provided. I did the same with the top half, too. The heating elements can be cut down in length, which is required. You can NOT, however, cut them width-wise. You can cut up to 2 holes for the hog rings, but I was able to slide the heater under the hog rings without any hassle. I didn’t even connect a couple of them back, but there is room to do so. Make sure the heaters are pushed down into the channels, so the hog rings and ties don’t stick up, and the seat still looks stock.

The center console has plenty of room for the cable, but I put the relay under the seat and secured it with ties – the two lines can go right underneath the center console trim with ease. You will need to drill a hole 13/16″ to accommodate the switch, but you can put it wherever you like. Here is mine:

Finished install:

It’s pretty easy to run the wire up the side of the center console, and over to the fuse box – there was plenty of wire to do so. I used the large metal bracket in the front, inside of the center console for a ground.

Go finish your beers and enjoy warmth! I have a Yukon with factory heated leather seats, and these heat up in half the time! I put mine on constant power, but I wouldn’t recommend that to others, as if it’s left in the high setting overnight, it will drop the battery voltage down to 10 volts -just below what it takes to start (I tested it) The reason I connected to constant is so if I am waiting in the car, and I don’t have the engine running, I can still have a fresh, toasty, Amish ass!!

[/url]

[/url]

[/url]

[/url]

[

[