Custom DIY Front Splitter / Chin Spoiler / Front Lip / Ground Effects

The Mopar lip kit is fine for most people, in fact, it looks quite nice. The problem I had is the cost, and the fact that everyone has that

one option. I have done a ton of research on splitters, lips, spoilers, etc., but I am in no way a car, or racing expert. Use my instructions as a guide – then put your own flavor on it. Not everyone will like this style, but you can see what I struggled with, and why I made the decisions I did. I hope you like it, but if you don’t, you can build yours any way

you want.Before you ask, a front splitter is designed to produce extra downforce at high speeds to the front wheels for better handling and traction. These are often used in conjunction with rear spoilers in race cars, and won’t have much of an impact on driving below 80 MPH. They usually fill the bottom portion of the car from just ahead of the front wheels to a few inches beyond the front of the car. Oh, and they also look freakin’ baddass!Typically, a front splitter should fill in the entire space in front of the wheels, and should not have any spaces or openings. My Dart has the Aero package, which means it is already covered under the entire bottom. It also means the aero panels protrude down past the fascia. If you put a flat piece of material under the whole thing, it can’t touch the sides b/c the oil drain area sticks down too far. A splitter should also be flat if possible, so I omitted the center area in the splitter, and left it as is. This also reduced the weight of my entire splitter to less than 3 lbs.Now the question everyone asks (go ahead): What’s it made out of? Alumalite. “Alumalite is a strong, aluminum composite panel made of with a high density corrugated polyallomer (CPA) core that will not swell, corrode, rot, wick water, or delaminate even under prolonged water exposure. Factory-baked polyester painted aluminum faces add high gloss brilliance and rigidity.”There are many ways to do this, and the cheapest would be plywood, and then covered in polyurethane resin to make it waterproof. The problem with this is weight. ABS plastic is also pretty expensive, and also heavy. I looked up what the professional racers use, and most of them are using some form of alumalite. It is incredibly strong and lightweight. It can also be bent, if needed, and is completely waterproof. The best way to describe it is two, thin aluminum sheets, separated by a corrugated material.

So then I researched, “Who else would use Alumalite,” and I found they use it to make signs! I reached out to some local sign companies and confirmed this. All you have to do is ask them for scraps. I needed something that was at least 72” x 26” – I ended up finding a piece for the price of a

12-Pack of Anti-Hero IPA (although he is my buddy, and did the graphics for

Dartlene Orangina)

The first thing I needed was a template, and a way to line things up. The easiest way to do this was to start with the Mopar Front lip. When tracing the lip, you have to be careful, and take into account the 7/8″ rise in the middle of the fascia. If you press the lip flat and trace it, along with the holes, once you hold your trace up to the car, you will find the outer edges and holes are too wide. Be careful to trace the piece while keeping it’s shape, holding the edges up.

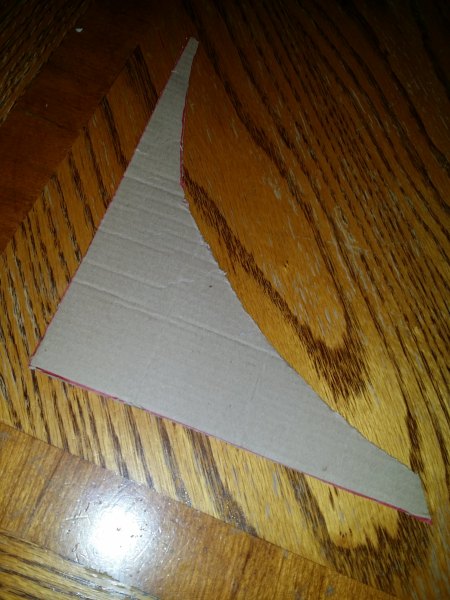

I followed the front angles of the car, but I wanted a little more aggressive appearance. I also knew that I wanted to wrap the thing in carbon fiber, and if you’ve done any wrapping, you’ll know how difficult it is to wrap around a curved edge. If you want to try this method, you’d have to cut along the top edge, and use a separate piece for the front / bottom. I used cardboard to create my original template, so I could mess with it, as well as hold it up to the car for rough placement. I was concerned the cardboard would bend, but the final material would not, so I also had to keep in mind the upward arch in the middle if it is attached flush to the fascia.

Now that I had my template, I dry fitted it to the car to make sure. Then I traced it onto the alumalite, and cut the front shape and the inner circle, leaving a bit extra on the inside, which could be trimmed. As it was, I had to adjust the holes a little bit after the final cut, as I was using the same holes to secure the aero panel and the Mopar front lip, if you had one. The 4 screws in the rear connected perfectly to the cut splitter, but it had to bend up too much in the middle to work, so I needed spacers. I took some brass tubing I had lying around, and cut it into (4) 7/8” pieces. Then I sanded and painted them black. Washers were used above and below the splitter and spacers, and I found some wood screws that matched the thread of those metal clips in the aero panels. Lock washers were put on the very bottom to secure it.This is without the spacers:

Spacers:

Underneath the spacers:

Then I wrapped the splitter, easily terminating the ends of the wrap on the bottom, as no one can see that, unless the car is on a lift. For extra credit, I guess you could wrap or paint the bottom, too.

Rough mockup:

After I had the flat shape, I added my side fins, using simple nut and bolt connections on either side. I lined up the outside to the shape of the car, and the back to the wheel well. I originally was going to bend the alumalite into the fins, but I wanted something that looked a little better and wasn’t as thick. The edge of alumalite looks a like cardboard, so it needs to be covered, wrapped, or filled in. I found some thin aluminum and could easily cut and bend it as needed. Then I simply drilled a couple of holes in the new “L” shaped wings, and bolted from underneath. Shazam!

I mounted the splitter using the 8 holes in the bottom fascia that connects the aero panel. The rear 4 were factory screws, into the factory holes, and the front 8 were factory holes, with longer, wood screws that matched the thread size. I later painted the silver bolts black, as well.

Finally, the last step was the rods. I already had replaced the grilles with mesh that had medium sized holes. I painted a couple washers black, and used them in front and behind the grille to secure it, and then bolted it to the splitter. I was able to do all of this without removing the fascia, but it was a bit tricky squeezing in and securing the nut on the backside. They are adjustable, so you can make them ultra-secure. I’m not saying you should stand on this thing, but it is very secure, and has lasted, so far!

I later added a lip underneath the splitter, to give it a more “lowered” look – I think it makes it more aggressive, but certainly works without it:

[/url]

[/url]

[/url]

[/url]

[

[